Sustain the Planet

Sustain the Planet

We aim to preserve and restore our planet through continuous investments in solutions that improve biodiversity and reduce the impacts of climate change. Combating climate change will require investment and innovation in scalable solutions. We are working on finding and implementing these solutions to help reduce our overall impact on the natural environment.

SUSTAIN THE PLANET GOALS FOR 2025 AND BEYOND

Reduce absolute Scope 1 and 2 greenhouse gas (GHG) emissions 64%, Scope 3 emissions 42%, and Scope 3 FLAG emissions 30% by FY2030 from a FY2021 base year.

Reach net-zero GHG emissions across the value chain by 2050.

By 2025, reduce water usage by 10% within our own operations below FY2018 levels and across our supply chain from a 2020 baseline.

Procure 100% renewable energy in Tapestry-operated stores, offices and fulfillment centers by 2025.

Reduce absolute Scope 1 and 2 greenhouse gas (GHG) emissions 64%, Scope 3 emissions 42%, and Scope 3 FLAG emissions 30% by FY2030 from a FY2021 base year.

Reach net-zero GHG emissions across the value chain by 2050.

By 2025, reduce water usage by 10% within our own operations below FY2018 levels and across our supply chain from a 2020 baseline.

Procure 100% renewable energy in Tapestry-operated stores, offices and fulfillment centers by 2025.

PRIORITY

Climate Change

As the impacts of climate change intensify, we must adapt to the new normal, while working toward ways of doing business more responsibly. This goes beyond the products we sell. Climate change directly impacts the communities where we operate, often disproportionately affecting marginalized communities. We look to leverage the scale of our business and innovation to contribute viable solutions that mitigate risks to our company, and more broadly, the planet.

PRIORITY

Engaging Our Suppliers

Our suppliers play a critical role in helping us realize our environmental and social ambitions. We consistently partner with stakeholders across our value chain to work toward more responsible practices that their businesses can incorporate, especially through increased implementation of environmentally preferred manufacturing practices and the use of preferred materials.

PRIORITY

Renewable Energy

We are committed to procuring 100% renewable electricity in Tapestry-operated stores, offices and fulfillment centers globally by 2025. To achieve this goal, we look at our operating geographies regionally to make the best energy sourcing and purchasing decisions. We are working with a third-party energy procurement team to source renewable energy for our retail stores in deregulated electricity markets using green e-certified Renewable Energy Credits (RECs). In FY2023, 80% of Tapestry’s global operations were covered by renewable electricity, up from 67% in FY2022.

PRIORITY

Water

In FY2023, we attained a 10% reduction in water usage from our Tapestry-owned retail stores, corporate offices and fulfillment centers in North America compared to our FY2018 baseline

PRIORITY

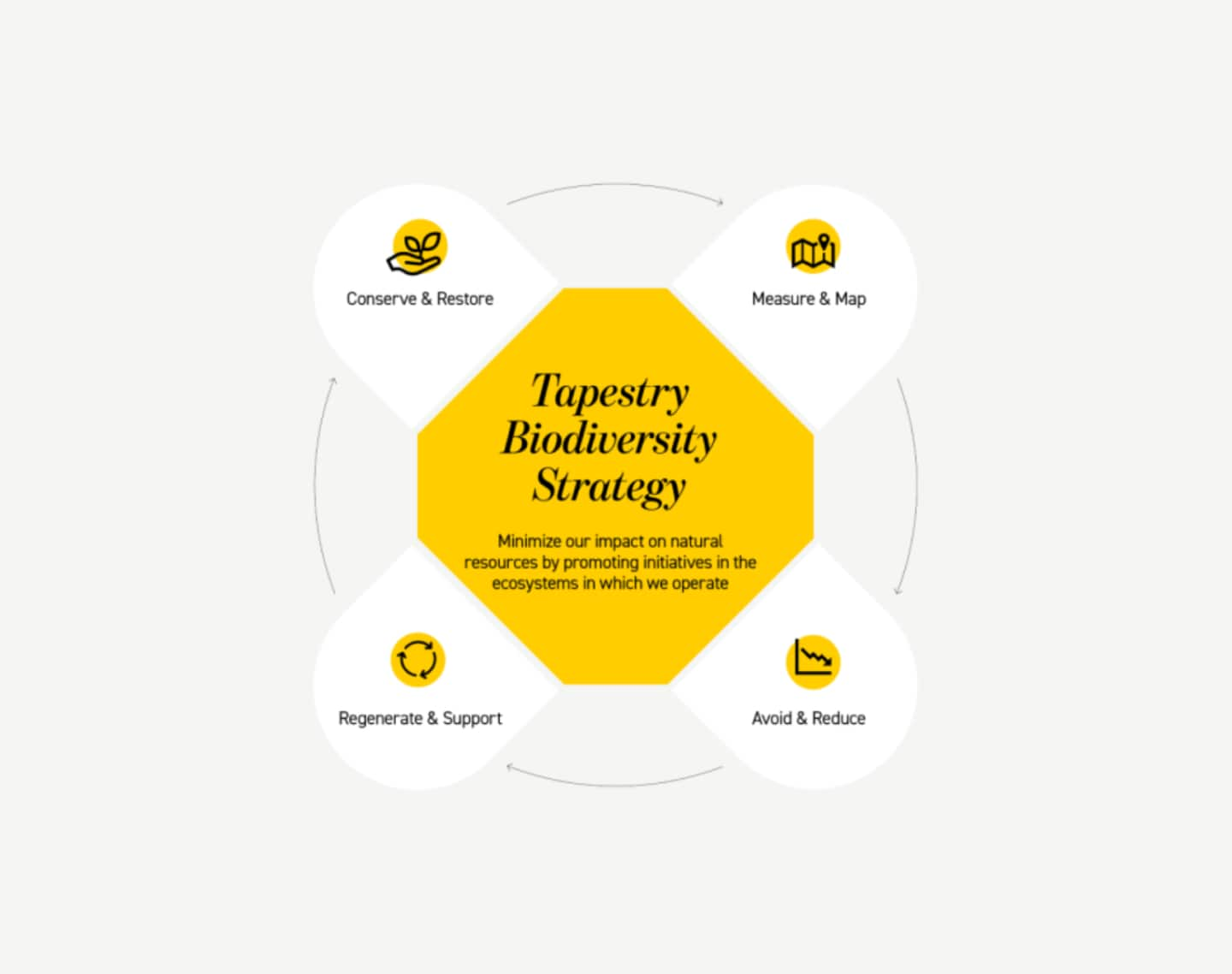

Biodiversity

As biodiversity and climate change are intertwined, we understand the importance of natural resource protection and restoration. We know our business has an impact on natural environments and we have an elevated responsibility to reduce that impact where we can. Tapestry’s biodiversity strategy aims to minimize our impact on natural resources by promoting biodiversity initiatives in the ecosystems in which we operate, and has four key components.

Highlighted Initiatives

Tapestry Aligns Reduction Targets with the Science Based Targets initiative’s (SBTi’s) FLAG Guidance.

In the time since we submitted our goals to the SBTi for validation, we reviewed the draft Forest, Land and Agriculture (FLAG) guidance and deemed it relevant for Tapestry’s GHG emissions targets. As a result, we have updated the set of targets we announced last year and hope to receive verification from the SBTi by early 2024. The FLAG guidance includes more stringent thresholds related to GHG emissions reductions tied to companies in land-intensive industries, and we are among the first in the fashion industry to align with these standards.

Supporting Community Solar Energy in Illinois

In FY2023, Tapestry signed a 15-year agreement with Pivot Energy to purchase Impact Renewable Energy Credits (RECs) through the development of six community solar projects in Illinois. What makes this project unique is that, unlike traditional REC purchases, Impact RECs provide additional clean energy in areas with lower solar resources and provides direct investment in local communities. These projects are expected to go

Tapestry joins Deforestation-Free Call to Action for Leather

In FY2023, Tapestry signed onto the Deforestation-Free Call to Action for Leather organized by Textile Exchange, Leather Working Group, and World Wildlife Fund. The Call to Action unites leading fashion brands in their commitment to collaborate and be held accountable for preserving natural ecosystems and improving the environmental impact of leather supply chains.

Learn More About: